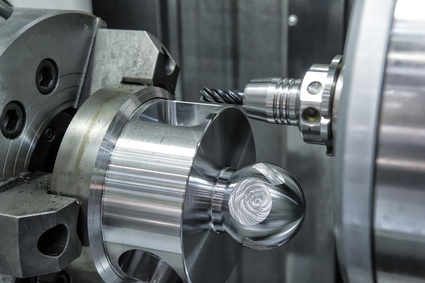

The individual tool-making is one of the most important base for many companies. To achieve the best quality for your products you need customized tools which are optimized for the own requirements. If you are looking for a reliable partner for your tools HAMCO is the best choice

We have three production-processes for your products:

Dip-moulding, direct-coating and injection-moulding.

We have a big standard assortment of dip moulded articles like our round-caps, rectangular-caps, protection-caps, handles and grips. Of course also the production of your special parts is possible with the dip-moulding process.

In addition to this we have much experience with the direct-coating of metal-parts

In our injection-moulding-department we produce high-precisely special parts and also standard parts like washers, grips and handles, protection buffer and tube-connectors.

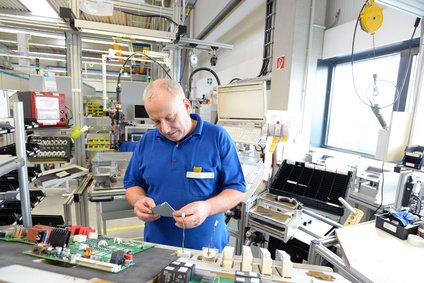

The assembling of different devices is a special service for our customers. We also offer special-packaging, imprinting, punching and other reworks. If you need a special service for your parts please feel free to send us your inuiry.

We have extended our machinery with a 2-components-machine. It is an Arburg Allrounder 570S 2200-800 with Multilift Select and a movement path of X=900 Y=1200 Z=1600 and a clamping force of 220 tons. With this machine we can produce parts up to almost 500 ccm (depending on the density of

2 components ? We can do it ! For some applications the use of a 2C injection molding process makes sense. In this process we use two different materials and combine them in one article. So we are able to use the features of both materials as you probably know

We have extended our assortment. In addition to our plastic caps, grips and plugs we have some new innovative products - please visit us

We are happy to present our new tube connectors which are available for different standard-tubes. You can find an overview of all available sizes here or in our download-area.